For our Q2 Grid Transformation Forum, it is our pleasure to introduce Charles Johnson and Christopher Johnson with Ontario-based Amidyne Solutions. Here, we share a case study about Amidyne's innovative approach that is changing the way utilities manage PCB testing and inspecting transformers.

Introduction (A brief history of PCBs)

Beginning in the early 1900s, polychlorinated biphenyls, or PCBs, were added to the oil in transformers across the globe because of their insulating and coolant properties. Comprised of man-made materials, PCBs were widely used due to their non-flammability, chemical stability and insulating properties. However, widespread realization that PCBs were harmful emerged in the late 1960s and early 1970s, with significant incidents like the Yusho poisoning in Japan and the discovery of PCBs in birds in Sweden sparking public and scientific concern. By 1972, scientific evidence indicated that PCBs posed a serious threat to the environment and human health.

In 2001, 152 countries joined forces to sign the Stockholm Convention, which is a treaty requiring countries to eliminate concentrations of PCBs above 50 ppm in equipment by January 1, 2026, and manage contaminated waste by 2028. While Canada, Europe, South America and most of Asia/Africa adopted this convention, the United States never ratified its commitment in Congress.

Despite transformers being changed out over time, PCBs in high concentrations still exist in approximately 2-4% of transformers, where utilities have not completed a full sampling program for their removal. In the United States and other countries, PCBs remain a serious concern.

The challenge

The traditional process of sampling transformers for PCB contamination involves de-energizing transformers for three to four hours, removing the lid from the container and taking an oil sample. Not only is this costly, labor-intensive and time-consuming, but it also means that utilities’ customers will be without power during that time. It is also difficult to manage administratively, especially where several transformers are in scope, and many customers will need to be notified of power interruptions.

Faced with these constraints and the approaching 2025 compliance deadline, utilities like Hydro One required a testing methodology that was safe, accurate and scalable without interrupting operations with volumes exceeding 180,000 transformers.

Innovation through collaboration

Ontario-based Amidyne Solutions has long been a leading utility and nuclear services provider focused on end-to-end project management, engineering, design, testing and software solutions. In 2019, the company began looking for a testing laboratory partner. Known for its technical expertise and reputable work in utility testing, Powertech Labs was a natural choice for Amidyne to approach.

Powertech Labs Inc. is one of the largest testing and research laboratories in North America, situated in British Columbia, Canada. Powertech engineered an innovative solution to support Canadian utilities' mandate to comply with the Canadian Environmental Protection Act to stop using any electrical equipment containing more than 50 ppm by 2025. Powertech developed a tried and tested transformer oil sampling solution through extensive laboratory testing and collaboration with Canadian utilities to develop the methods and equipment for reliably and safely sampling pole top and pad-mount transformers.

The turnkey solution consists of live line tools, sample seal kits and oil analysis. Powertech tests and reports all oil samples for PCB levels per ASTM D4059 at Powertech's ISO 17025 accredited laboratory.

Powertech found the ideal partner in Amidyne to expand the use of its transformer oil sampling and analysis solution beyond its current client base.

During a series of discussions, the Powertech team demonstrated several of their technologies to Amidyne, including one innovation that immediately stood out: a live-line PCB sampling method using hot sticks.

"Once we started analyzing the technology, we realized we could help them improve their tools.," said Amidyne Solutions CEO Charles Johnson.

Evan Waugh, project engineer with Powertech’s Transmission and Distribution Mechanical Lab, agreed with Johnson’s assessment. “Amidyne’s app was a significant improvement to the field operation process by providing a streamlined platform for compiling transformer data,” Waugh explained. “The real-time data review and GPS-based mapping system were excellent features and complimented Powertech’s tools and oil analysis.”

Amidyne then licensed Powertech Labs’ live-line testing technology and enhanced it by integrating digital tools and making improvements to the tools. This included:

- An inspection process using a custom-designed 40’ phone mount, which removed 68% of transformers from requiring sample – a significant savings in cost

- Real-time data review and program management

- Improved data management, including integration into Hydro One’s database

- PCB Sampling tool refinements and improvements.

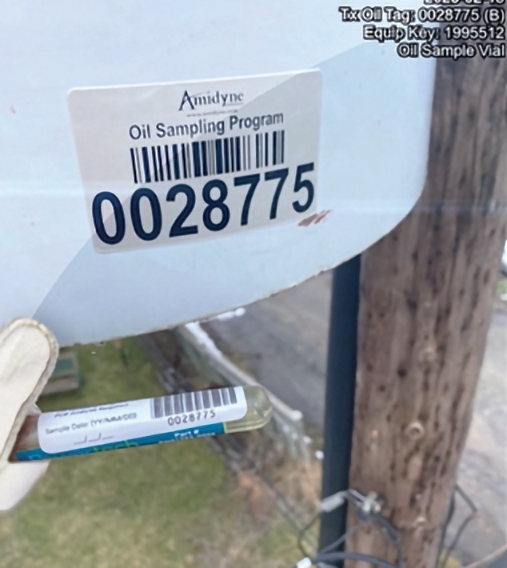

- GPS-based mapping system with scannable barcodes for quick transformer identification

- Real-time image sharing to enable instant quality control and remote feedback

- Color-coded visual mapping tool to show site access difficulty and operational tracking

Using the app, fieldworkers could instantly verify transformer sites, scan barcodes and record inspection and testing data. Reviewers could monitor progress remotely, suggest immediate corrections and ensure data accuracy in real time significantly reducing the processes involved with inspections and testing.

Even more impressively, Amidyne's solution was up and running within just three months of their initial collaboration with Powertech Labs.

From trial to expansion

Initially, Amidyne Solutions introduced its enhanced live-line testing technology to a member of Hydro One’s environmental team, who agreed to test the system.

The initial trial using Hydro One’s transformers ran from May 2022 to March 2023, pausing briefly and resuming in January 2024. For the first phase, Amidyne was provided with 1,000 units to test, which the utility immediately increased to 6,000, due to the speed and efficiency of Amidyne’s system. Within a few months, the trial eventually scaled to close to 180,000 units.

The work was completed on time, with zero safety incidents and at a significantly lower cost than the traditional sampling method.

As the testing progressed, Amidyne began using the mobile app for different projects, including pole and transformer replacements, switch installations, feeder quality improvements and post-storm assessments.

Looking at the future

Amidyne’s solution has not only transformed how utilities can manage PCB testing and transformer inspections but the solution is now being expanded internationally. As a result of its success with Hydro One, Amidyne has initiated discussions with utility providers in the United Kingdom, Brazil, Costa Rica and other Canadian utilities. The company is also expanding its U.S. presence through industry events and strategic partnerships.

The project illustrates how collaborative innovation, driven by regulatory compli- ance and operational necessity, can result in scalable, effective solutions. The live- line PCB testing system now serves as a model for utility modernization under environmental constraints

Conclusion

The partnership between Amidyne Solutions and Powertech Labs, with operational input from Hydro One and Valard Construction, demonstrates the potential of industry collaboration to address complex environmental challenges. By reimagining how PCB testing is conducted in the field, the project achieved regulatory compliance without compromising operational continuity–marking a significant step forward in utility asset management and environmental responsibility.

Charles Johnson is the co-founder and president of Amidyne Solutions Inc. His three-decadelong career as an entrepreneur has focused on cleantech industries, including owning companies manufacturing innovative insulation products; leading-edge electronics and chemical solutions for drinking water; as well as services and products for the power generation, transmission and distribution industries worldwide.

Chris Johnson has more than 20 years of experience leading teams specializing in innovative technologies and project management. He has a degree in electrical engineering and an MBA. Before joining Amidyne, Johnson led a technical services team of more than 200 people.