Imagine a university lab where students, professors and industry experts come together to develop an integrated hardware and software solution. This dynamic environment fosters innovation, with each participant bringing unique expertise. Ph.D. candidates collaborate with industry experts to design hardware and create software algorithms, testing their prototypes in real-world environments to develop viable industry solutions.

This collaboration between academia and commercial organizations leads to groundbreaking research and practical applications that benefit society. A similar collaborative spirit thrives in the utilities industry. Just as in academia, the utilities sector shows that working across functional boundaries leads to remarkable outcomes. Utilities can leverage internal teams, engineering partners, technology vendors and research organizations to drive innovation.

As electric utilities navigate the ever-increasing requirements to support sustainability, reliability, resilience and deal with workforce transitions and tech advancement, these evolving relationships within the engineering and technology ecosystem become crucial for innovation. Shifting from historical transactional interactions to integrated partnerships fosters continuous learning, technological advancement and mutual benefit. These collaborations enable utilities to minimize trade-offs between cost control and innovative investment. Working closely with research institutions and suppliers, utilities can refine workflows, enhance capabilities and drive greater overall success. One such example is Looq AI. Initially a university proof of concept, this solution evolved rapidly to early adopters. The goal is to enhance workflows with AI-enabled asset capture through strategic partnerships. Working with firms like Aquawolf and research organizations, Looq is helping the industry identify cost and time reductions compared to traditional surveys, fostering the rapid adoption of innovative solutions for a more sustainable and efficient utility system.

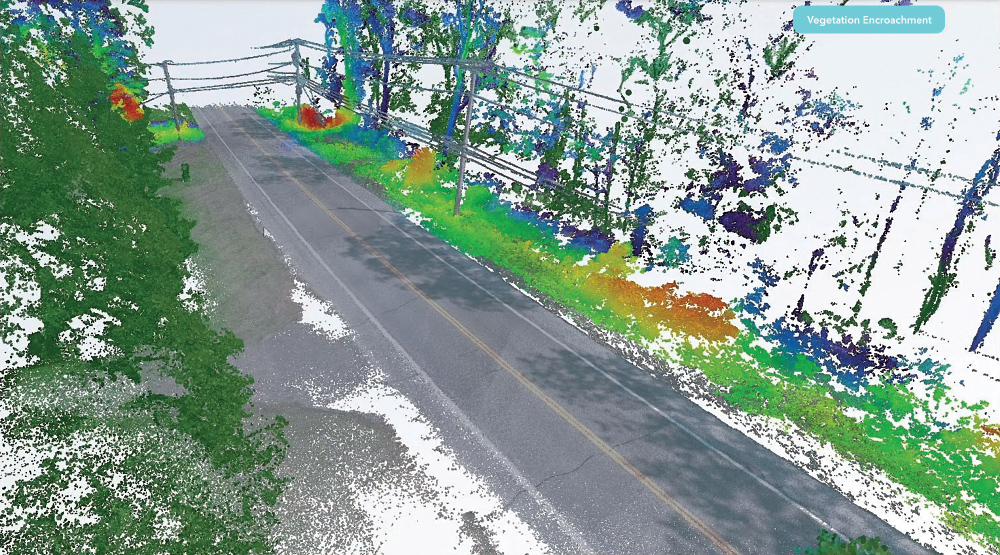

To identify and address potential interruptions from overhead systems, feature classification and insights built into capture workflows can help to anticipate issues. Not only would this help to optimize work for greater crew efficiency and provide potential cost savings, but also it has the potential minimize customer interruptions leading to improved reslience. Source: Aquawolf

Modernizing data capture

The growing need for accurate, up-to-date records necessitates continuous capture and modern data management solutions. Historically, information was derived from original engineering drawings or outdated as-built records, requiring multiple field trips to capture existing conditions for upgrades. This process was (and still can be) labor-intensive, time-consuming and expensive. Today, advancements in capture technology, such as high-resolution digital cameras, drones and automated processing, have revolutionized the industry. Photogrammetry, combined with AI and machine learning, produces precise, cost-effective 3D models. These digital representations integrate high-resolution textures from photogrammetry and precise structural details from LiDAR. Innovative teams incorporating this captured data with GIS, engineering and IoT data into digital twin environments gain data-driven insights that enhance business outcomes. This justifies investment in digital transformation, facilitating seamless data sharing and integration across platforms.

Continuously updated digital twins lead to smarter utility infrastructure. Yet, despite the benefits, surveying areas that include millions of points and large datasets can still create a hefty price tag. Given that their systems are ever-changing, utilities may hesitate to invest in additional innovative technologies or change workflows. Partnerships with research organizations, engineering firms and software vendors can mitigate these costs and drive innovation. This collaborative approach allows utilities to leverage innovative technology while managing expenses and change effectively. And the results have the potential to be transformative.

Embracing new ways

Taking care of the grid is not simple or easy. Diverse needs and tools make the inspection and diagnosis of large infrastructure assets like distribution overhead fragmented, slow and laborious. In some instances, old-school tape measures and clipboards remain part of the process. All of this can result in fragmented survey and engineering, decisions made off information that is likely outdated. On average it takes about 60 minutes per pole survey. Considering the number of poles in North America, that extrapolates to about 200,000 man-years to survey the poles. And while surveying poles sounds simple, it is high touch – costly, error-prone and comes with a high risk of accident/injury.

This new approach addresses asset capture and modeling in a complete and scalable way providing an unprecedented level of detail for survey, structural analysis, electrical verification, vegetation encroachment and GIS applications. The solution can improve fielding workflows at the start of a project, throughout construction, for handoff of as-builts and inspections and maintenance. This approach may in fact surpass what aerial, UAV and vehicle data collects can match because there are fundamental visibility and resolution limitations. This new approach speeds the process for pole fielding to approximately 250 poles/day – in some instances that is 10 times faster than traditional work. Looq claims this new approach provides post-processing/pole modeling three times faster. This means getting the updated information into the hands of decision-makers quickly and more efficiently.

For inspections and maintenance of utility assets, the working hypothesis for the solution is by accessing updated information more often (vegetation cycles or overhead equipment inspections that can happen more often without increasing crews) provides insights for prioritizing work and better scheduling. This, in turn, could help them to reduce the customer interruptions caused by tree contacts and overhead equipment failures. While Looq boasts about these improved workflow claims, they understand that the proof is in allowing others to evaluate and prove its accuracy and value. They are doing this directly with Central Hudson Gas and Electric as well as through early adopters like Aquawolf, McElhanney and AJS.

Piloting technology and new workflows

Research organizations can leverage the expertise, technologies and solutions to advance research and development in energy while benefiting from the specialized expertise of the vendors. Collaboration between electric utilities and their supplier ecosystem along with these research organizations can help to address challenges and augment technological advancement. These partnerships are crucial for moving theoretical research into practical, implementable solutions. For example, EPRI’s Incubatenergy Labs program matches early-stage technology companies with electric utilities in pilot projects demonstrating new technologies and products that address critical industry needs.

One such pairing saw that Looq was partnering with Central Hudson Gas & Electric in July 2024 to rapidly capture, create and analyze a large, representative data set of distribution poles, lines and substations. This project included the following:

- Models of 2500 poles and 5 substations

- 3D point clouds

- Panoramas

- Ortho-images (nadir view)

- Segmentations of lines, poles, vegetation, ground and other features

- Extraction of line-pole geometry for loading analysis

Chris Gilbert, manager of R&D and Innovation, at Central Hudson Gas and Electric, says, “While we are only at the capture stage of this project, ultimately where we would like to be is delivering greater resilience in the grid – where customer interruptions from our overhead system due to equipment faults and vegetation impacts are rare and quickly addressed.”

Large-scale data capture and automated 3D intelligent model creation are now easily in reach for electric utilities seeking to improve documentation of their distribution and substation assets. Improved segmentation, classification and defect detection are key to creating additional value for maintenance and vegetation management applications. Todd Hylton, VP Strategy, Looq AI says, “Working with the team at Central Hudson, Looq was able to understand their pressing needs in defect detection and vegetation management in addition to the data capture and geometric analyses that were the focus of the project. Our work together continues as we develop these new capabilities in pursuit of a more reliable and more affordable grid.”

The utility and Looq have agreed to continue working together to develop these capabilities, which will leverage the data collected and the learnings derived from this project. Gilbert concludes, “With enhanced access to accurate, up-to-date data, we would be able to more proactively manage potential risks, optimize maintenance and bolster system reliability. This approach builds on our existing strengths to deliver an even higher standard of dependable service that our customers can continue to count on.”

Testing AI-enabled asset capture at Aquawolf

With this new process, Aquawolf is proving they can capture, analyze, deliver reliable, high-quality digital twins and help their clients transform their approach to both small and large-scale photogrammetry. Aquawolf, a wholly owned subsidiary of Mammoth Energy Partners LLC, manages multiple types and aspects of projects including preliminary electric transmission and distribution line routing; natural gas pipeline conceptual design; detailed transmission and distribution line design, pipeline design and construction support. Many of the projects they manage are resource and time-intensive and often require working with 3D data.

Aquawolf is testing and implementing an innovative approach to supplement traditional surveys that is one-third the cost. Historically with projects like these, Aquawolf would send out crews to walk every mile of a site and simultaneously they would send crews to capture an entire area – often 50-60% more data than was necessary. Traditional processes might include drones or fixed-wing planes; they would take photographs, process topographic maps and transcribe all the features. This could include billions of points of data meaning they would need to narrow to what was needed for the project using civil engineering tools for thinning the data.

With their new workflow using a novel AI-enabled camera technology, they have a survey grade point cloud from which to work that has replaced an aerial flight, the scribing process and most of the topographic processing. This is all due to the back-end AI process. The team can walk around and capture while they evaluate the site. Everything that humans see the camera can see as well. This new capture process eliminates the need for data to be collected by both surveyors and field technicians and can minimize the use of civil tools for thinning the data. “Survey firms will bid on an entire package. We no longer need to do this,” says Alex Richards, PE, President, Aquawolf. “Instead, we walk every mile of an overhead project with Looq AI’s hand-held camera. We are developing the digital twin while on-site and in one trip as opposed to multiple. There is no need to re-field because we get everything necessary in a single visit.”

On one project the Aquawolf team was working with rough terrain dense with vegetation, the alignments were in the trees. The original survey had gaps in both topography and features because they were both obscured. “With boots on the ground, we got into locations the survey could not. We got under the tree covers and could see through all the obstacles,” says Blake Darling, PE, PMP, director of Engineering Underground Programs, Aquawolf. “Filling these gaps surgically means we deliver a better product, with 30% in cost savings in the amount of data that needs to be processed. This has been a key component of helping Aquawolf maintain its reputation for agility and high-quality engineering and design.” This new workflow has helped Aquawolf spend their time on more valuable work. Rather than spending considerable time aggregating terabytes of unnecessary data, they are enabling key decision-makers and engineers. This approach means fewer truck rolls and fewer crews engaging with energized assets, working in rough terrain or dodging vehicle traffic. The benefits of this improved process include optimized resources, lower costs and improved safety.

Aquawolf is providing engineering and design services on a large western utility for a 10-year program to underground all high-risk electric distribution circuits in the backcountry where there are high wind, fire and other threats to the overhead equipment. Due to the program's scale, the utility sent surveys to collect data way before the design. However, the survey did not cover 100% of the area needed.

Aquawolf decided to implement their new capture workflow allowing them to capture rich data easily and rapidly beyond what they would normally get from traditional land surveys. Because it is so easy to capture the site, Aquawolf was able to collect a significant amount of data without needing to know exactly which data points would be relevant once they began designing. In a traditional process, they would have figured out first what they needed and requested specific survey requests requiring detailed explanations to the surveyor. Often there is a great deal of back-and-forth communication happening because someone forgets specific features or needs to expand the survey area – all of this can be time-consuming and expensive. “We capture everything we see while walking the site and all of that becomes the digital twin,” says Darling. “Even the first couple of times we used the technology, we had this intuition that we were approaching survey accuracy and could supplement the traditional survey process at one-third the cost of traditional land survey.” Aquawolf can ask a survey to establish a control network, then they verify the points in their scan to match what the surveyors found tightening up the accuracy – and all of this is at a fraction of the original cost.

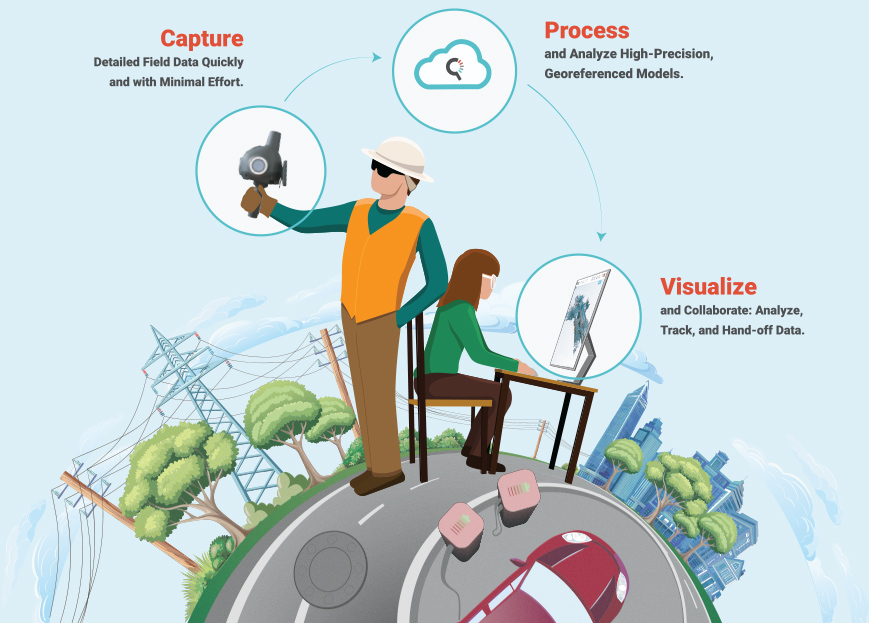

When the captured data hits the cloud, there is an advanced algorithm working to craft a high-precision, geo-referenced 3D digital twin and 2D images that can be used to perform asset analysis. “The real magic is the AI-enabled software. We can automate 3D modeling and seamlessly interact with digital twins enhancing the collaboration with our client and helping to streamline their decisions,” says Richards. “This all happens in a dashboard where everyone can view, analyze, track, hand off the project.” Working more collaboratively with utility clients is much simpler because everyone can view, interact and collaborate on survey-grade 3D models within the data portal.

Through proving this new workflow in their overhead projects, Aquawolf sees opportunities to improve planning and design projects as well as value-added services that can supplement utilities’ inspection and maintenance.

Utility overhead distribution upgrades – These projects are smaller in scale such as a highway crossing or road widening requiring updates only to a few spans. Typically, utilities do not want to wait or pay for traditional LiDAR because they do not need the entire line point to point. Aquawolf will collect the required area much faster and create an accurate 3D model from that data which can be quickly incorporated into more powerful modeling software providing an accurate representation of current conditions.

Joint-use - When communications companies want fiber optic attachments to utility poles, they must take measurements and provide this information in their request. Using this new workflow, the team at Aquawolf can quickly capture and deliver the necessary data including measurements and proof of clearance. When needed, they can provide a 3D model to support simulation and analysis such as pole loading.

Overhead transmission design and documentation - Aquawolf can provide supplemental data for overhead transmission design by capturing wires and structures for modeling. Their new process allows for rapid capture of specific poles or spans, seamlessly integrating these into existing LiDAR datasets, thus expediting data updates for utilities. Traditionally, requesting a LiDAR vendor go back and collect this could delay data updates by several months.

Many lattice towers have been operational for more than 60 years and through these years of inspection and maintenance, most have undocumented replacement parts. Aquawolf can utilize this new workflow to get a quick scan of each tower during project visits allowing them to provide immediate documentation to the utility. This could include a more accurate record of the tower and any damage, bolt counts and other structural assessments. By leveraging this new approach, these scans are processed swiftly for use with engineering analysis applications. This ensures that current tower conditions are accurately reflected in the engineering models.

Collaboration for the benefit of many

Through more collaborative partnerships, surveying and engineering firms can create a continuous cycle of innovation and application helping them to stay at the forefront of industry advancement and offer more sophisticated and economical solutions to their clients. Amanda Jones, CEO of AJ Surveying, “The use of this technology is a game-changer for us. It gives us the opportunity to capture a large amount of survey-grade data.”

Kevin Grover, advanced technology leader at McElhanney Ltd says, “I haven’t been this excited about a new 3D capture technology in a long time. The speed and quality of the survey data are paramount to other 3D technology on the market today. We are excited to be an early partner.”

Darling concludes, “The platform has become an indispensable engineering tool in our fielding tool kit. Their unique hardware and groundbreaking back-end processing have enabled our design teams to capture highly detailed and accurate field conditions in the absence of existing survey data. During all phases of design, we have been able to fill holes in our existing survey base maps quickly and reliably with rich data which keeps design moving forward while we wait for traditional land survey.”

The objective of the early adopters is to help them align the hardware and software evolution to the needs of their clients and the services and value they want to deliver. Such strategic collaborations not only foster technological advancement but also strengthen the relationships among the parties involved, creating an ecosystem focused on innovation and operational excellence. Richards concludes, “While the qCAM is a simple piece of hardware, the software has almost limitless possibilities for the future. The team has been receptive and innovative in the types of data tools they deploy regularly – automation of point processing, point cloud classifications and the ability to manipulate this inside the user interface. We continue to have conversations about the next improvements.”

The growth of the relationships between utilities and their research and supplier ecosystem is evidence that such alliances can form a better framework for advancing grid modernization efforts. Sara Chilcott, Grants Coordinator /2024 IEL Project Manager says “Our partnership with Looq AI has been a collaborative journey, providing invaluable learnings for both sides. Looq’s openness to feedback has been instrumental in refining their technology to align with our specific needs and improving our workflows. Their commitment to innovation and responsiveness has strengthened our ability to take meaningful steps toward achieving our ideal state of a more resilient grid. As we continue this project, we’re excited to not only advance our own goals but also share these lessons learned to help other utilities implement similar solutions, driving progress across the industry.”

These collaborations create the necessary environment for rapid development and implementation of technologies that are not only effective but also adaptable to the changing landscape of global energy.

Teresa Elliott is the vice president of marketing Looq AI, bringing more than 20 years of experience in B2B software and services marketing in AECO/Infrastructure. Elliott has worked with innovative desktop, cloud technology, SaaS/PaaS and photogrammetric solutions from Autodesk, Bentley Systems, Intergraph and others.

Teresa Elliott is the vice president of marketing Looq AI, bringing more than 20 years of experience in B2B software and services marketing in AECO/Infrastructure. Elliott has worked with innovative desktop, cloud technology, SaaS/PaaS and photogrammetric solutions from Autodesk, Bentley Systems, Intergraph and others.

She has authored articles and delivered professional design hours for water, cities and energy verticals. She earned her Executive MBA at Auburn University and a BS in accounting at the University of Alabama in Huntsville. Elliott recently completed certificates in AI Applications for Growth at Northwestern University’s Kellogg School of Business and Design Thinking at Stanford University.