Load growth, climate change and aging infrastructure are taking a toll on power grid reliability. Any one of these factors could be a challenge. Combined, these circumstances make grid visibility crucial to preventing and managing outages effectively. Utilities can get the insight they need with a solution that combines advanced analytics, intelligent line sensors, elastic computing and machine learning capabilities.

Forces to be reckoned with

Several circumstances make outages more common today than they were two decades ago. One is load growth, which can strain an aging grid.

A power sector consultancy based in Washington D.C. lays it out in a December 2023 report titled The Era of Flat Demand is Over.1 During the past decade, grid planners have forecast an annual growth rate of 0.5%. However, peak demand rose to at least 0.9% in 2023, and the report notes, “This is likely to be an underestimate.” Five-year forecasts jumped from 2.6% growth in 2022 to 4.7% growth in 2023.

This is happening when aging infrastructure also demands utility attention and investment, in part because aging infrastructure contributes to outage frequency and duration. The American Society of Civil Engineers publishes an infrastructure report card every four years. In the 2021 edition2, ASCE noted that some 70% of T&D lines in the U.S. “are well into the second half of their lifespans.”

Aging infrastructure is an issue for Canada, too, according to research conducted by the Canadian government.3 Even though 80% of that nation’s generation capacity is non-emitting, reaching the nation’s goal of achieving net zero emissions by 2035 will require $400 billion to replace energy infrastructure and expand generation capacity.

Meanwhile, climate change has contributed to increasingly frequent outages. Researchers at Climate Central, an independent group of scientists and communicators, collected power outage data from 2000 to 2021 that was reported to the U.S. Department of Energy by power providers.4 When looking specifically at major outages — events affecting at least 50,000 utility customers — 83% of those outages were attributed to weather conditions. Compared to the 2000 to 2010 timeframe, the annual average number of weather-related outages increased by 78% between 2011 and 2021.

A different study conducted by the Wall Street Journal noted that there were fewer than two dozen major outages in 2000 and more than 180 in 2020.

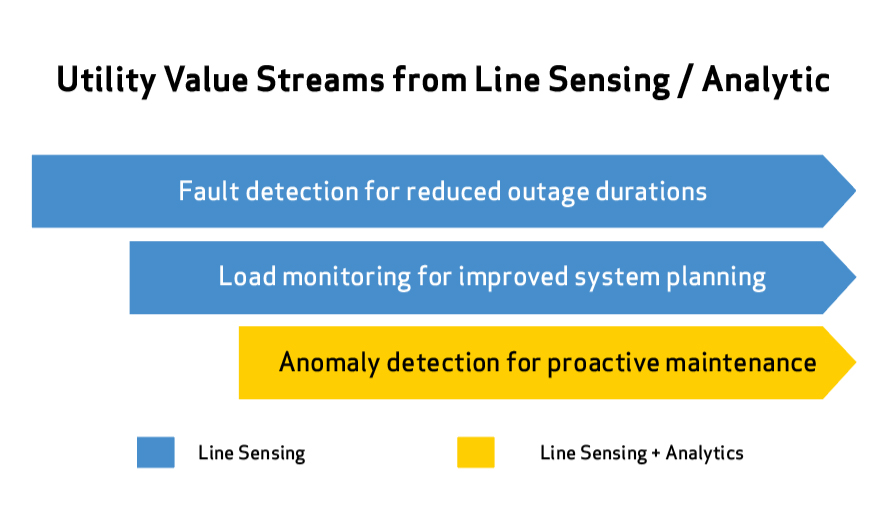

The good news is that there is a cost-effective way to predict, prevent and manage outages that will also help utilities prioritize investments and get maximum value out of existing assets through predictive maintenance. That solution, as noted before, is the combination of advanced analytics, elastic computing and intelligent line sensors. Intelligent line sensors capture system data for remote visibility from more grid locations. This data allows utilities to address reliability in three key ways. The first is detecting outages and pinpointing fault locations. The second is monitoring load for much more precise system planning. When you add in predictive analytics, utilities can perform a third key activity: detecting system anomalies for proactive maintenance that can help reduce fault occurrences.

Fault detection and location

Intelligent line sensors can be installed on overhead lines, underground cables, vaults or pad-mounted switches and in underground residential transformer cabinets. A best practice is to install sensors every 3-5 circuit miles. This enables enhanced system visibility along the feeder. A similar approach also works for lateral lines.

Data supplied by the sensors enables utilities to better triangulate the section of the distribution system in which the fault occurred. Grid operators can compare line sensor data to data from other systems, including SCADA, DMS and OMS. Alternatively, system operators can directly integrate the sensor data with these same systems using software APIs. Either way, the utility achieves a more precise diagnosis of the fault attributes (e.g. magnitude and phase) and location.

That narrows down the area that line crews will need to go out and inspect. Workers have fewer line segments to visit and less windshield time to put in before locating the fault and restoring power.

Line sensors have been proven to improve outage durations, which reduces SAIDI. The improvement is largely due to reduced patrol time, with some utilities reporting upwards of 65% patrol time savings. Reducing patrol time also saves O&M costs. In one case, a large utility in the southeast achieved an 11% reduction in O&M costs by using line sensing.

Another benefit of line sensors is a reduction in customer minutes interrupted (CMI). Some utilities have seen CMI drop by as much as 20% when sensor data is integrated with advanced distribution management system (ADMS) applications like fault location, isolation and service restoration (FLISR) or distance-to-fault calculations. In the FLISR scenario, grid operators link sensors with non-communicating reclosers or feeder relays, which allows these devices to participate in the FLISR schemes.

Load monitoring for improved system planning

Now, integrated system planning is more important than ever before. With the increasing adoption of intermittent renewable generation, utilities need to plan for the integration of variable supply as well as system management that may need to include wind or solar firming.

EVs will impact future load curves, too. Worse, EV adoption tends to occur in neighborhood clusters. One 2023 study analyzed new EV retail registrations spanning five years in 11 markets and found substantial evidence that peer influence impacts EV purchases.5 This means a local transformer could see overloading if households served by it add EV charging to their power consumption around the same time. According to an article in the Financial Post, Saskatchewan's power utility SaskPower found that “a cluster of 22 homes could only handle 11 electric cars before outages would occur.”6

Today, load data from the substation and circuit extremities are no longer sufficient. Utilities must know what’s happening along feeder segments and laterals for operational decision-making and longer-term capacity planning. They need to know what’s happening at transformers to support EV adoption. In the shorter term, they also need load data for switching decisions to ensure that circuits taking on new loads during an outage don’t overload.

Utilities also need visibility down the line for system optimization and reconfiguration. While the three phases of a feeder may look balanced at the substation, they can become significantly unbalanced at locations down the feeder. Phase unbalance can lead to uneven loading on transformers, conductors and other distribution equipment. The phase with higher load experiences greater stress, potentially leading to equipment overheating and early asset failure, which means another potential outage source.

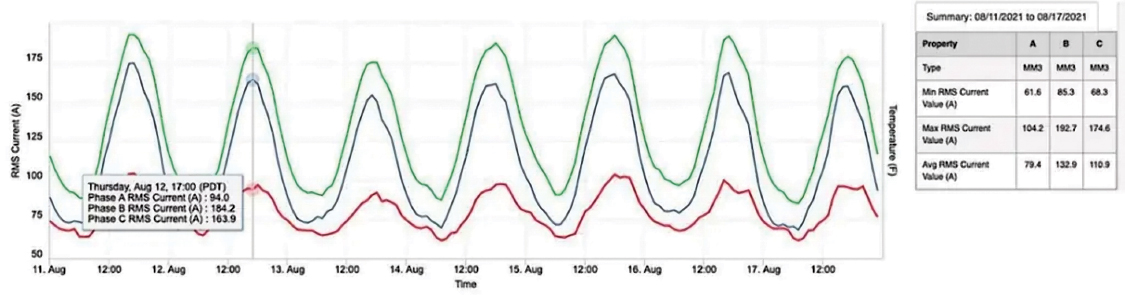

The graph below shows how system planners can identify a location with excessive load unbalance and initiate action to rebalance the load to gain efficiency and reliability.

Insight into transformer loading is another benefit of intelligent line sensors. Years ago, it was a commonly accepted practice to run assets to failure. Today’s supply chain constraints, reliability and resiliency expectations and lengthy wait times for critical equipment make this a risky approach.

When added to underground residential distribution transformers, line sensors detect faults on the primary side and continuously monitor transformer loading. This loading information helps utility engineers improve asset management and replace overloaded assets before they fail.

The graph shown is from a leading Southwestern utility and shows line sensor data indicating an overloaded transformer. This transformer was overloaded 150 times in eight months, with an average loading of 126% of its nameplate rating and a peak loading of 212% during this period. When a transformer is overloaded this severely, there’s a risk of an outage or transformer fire.

Operational data from intelligent line sensors enable grid operators to quickly identify overloaded transformers and replace them proactively. That delivers potential reductions in CMI and O&M cost savings as well as diminished legal risk related to fires.

Anomaly detection for proactive maintenance

You can’t predict all outages. Who would have guessed a raccoon would take out power for 40,000 people in Midtown Toronto, or a bird would drop a fish on a transformer, leaving residents in Sayreville, N.J. in the dark? Those were two of the more unusual outage sources in 2023.

Fortunately, two categories of outage causes are predictable: those caused by vegetation contact and those caused by equipment failure. This is possible because faults caused by vegetation contact and equipment failure are often preceded by subtle anomalies in high-resolution sensor data. If these anomalies are captured and properly classified, faults can be predicted and preempted.

Vegetation management is crucial to effective outage prevention. A study conducted by scholars from the College of Natural Resources at the University of Wisconsin-Stevens Point surveyed vegetation management experts at 71 U.S. and Canadian utilities in 2019 and 2020. The survey found that vegetation issues contributed to 23% of outages and 21% of lost customer minutes. An average of 21% of trees trimmed were in contact with distribution lines when vegetation management crews showed up to do their work.7

In some areas, vegetation management is even more important. Eversource Energy, a power provider to more than 3 million New England-based electric customers, shared its data with researchers at the University of Connecticut. That utility reported that as much as 90% of its outages were caused by tree contact in storms with heavy wind or snow in Connecticut, where forest covers more than half the state.8

University researchers used Eversource data to evaluate the effectiveness of tree-trimming operations. Among the findings, the researchers correlated a high level of vegetation management led to a 37% reduction in outages during severe storms. In less severe storms, outages could be reduced by 45% to 65%, depending on the level of vegetation management performed.

Often the single largest line item of utility O&M budgets, vegetation management costs can exceed $100 million annually for larger utilities. Given the potential impact of proactive, informed tree trimming, savings could be substantial.

Precursor anomalies also can be detected before equipment failures of insulators, cutouts, lightning arrestors, transformers, capacitor banks and other devices. If these failures are predicted, utilities can inspect feeder segments proactively for problems and make repairs before these equipment failures lead to unplanned outages.

A diversified approach is most effective for improving reliability

The complexity of today’s distribution grid challenges calls for breakthrough reliability solutions that improve power delivery in multiple ways. With three sets of use cases and value streams, intelligent line sensing coupled with advanced analytics and elastic computing offers a multi-pronged and quick time-to-value approach to improving reliability now and into the future. The fault detection and load monitoring value streams provide immediate ROI to operations and system planning teams. Achieving high probability prediction of outages takes time and effort, but the potential payback in reliability improvements and customer satisfaction can be a game changer.

Dr. Mirrasoul “Mir” Mousavi serves as head of advanced analytics and applications at Sentient Energy, where he leads a multi-disciplinary team of data scientists, power system engineers and software developers.

He received his Ph.D. in electrical engineering from Texas A&M University. He holds more than 14 U.S. and international patents and has published several journal articles, conference papers and book chapters. He also is a senior member of IEEE and IEEE Power and Energy Society (PES) and has contributed to a number of PES technical working groups.

1 https://gridstrategiesllc.com/wp-content/uploads/2023/12/National-Load-Growth-Report-2023.pdf

2 https://infrastructurereportcard.org/cat-item/energy-infrastructure

4 https://www.climatecentral.org/climate-matters/surging-weather-related-power-outages

7 file:///C:/Users/betsy/Downloads/UWSP-CNUCUVMSurveyReport_.pdf

8 https://www.mdpi.com/2071-1050/14/2/904#B2-sustainability-14-00904