One of the keys to reaching the cruise line industry’s target of net-zero carbon cruising globally by 2050 is switching from diesel-burning engines to shoreside electricity while in port. Although the technology can significantly reduce emissions to address climate change and improve air quality, one impediment to adoption has been the challenge of efficiently connecting ships of various sizes and shapes to shore power with cabling and equipment on piers.

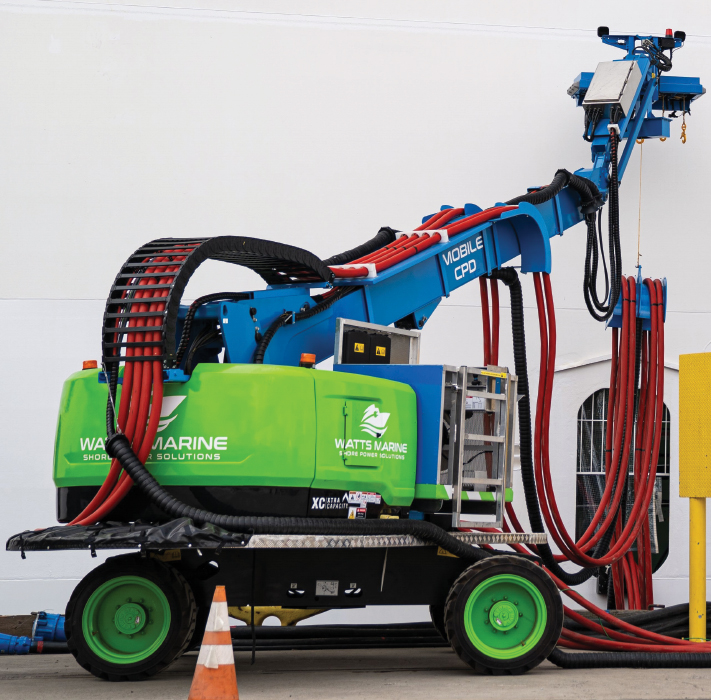

The Mobile CPD is a mobile manlift on a turret that rotates 360 degrees that we retrofitted from a Genie lift into an electrified cable positioning device.

While fixed systems exist for vessels to connect to shoreside electricity in port, the options are complex, expensive and occupy valuable pier real estate. Repositioning a fixed system to accommodate vessels of different sizes and configurations can take several days.

Now innovative, cost-effective mobile cable positioning devices (CPD) are facilitating shore power connections by moving the cabling strategically to the ideal location. The first such device has already been delivered for use at the Port of San Diego, California.

A mobile CPD is a mobile manlift on a turret that rotates 360 degrees retrofitted from a Genie lift into an electrified cable positioning device. The new mobile design simplifies moving the system to accommodate docked vessels of all sizes and configurations. The mobile cable positioning devices can be used with any shoreside electric power system.

A mobile device can be strategically positioned where the ship is docked and can then be moved to support another ship, say, 60 feet away. With a fixed system that is not possible, and it can take days to move it if that is required.

These mobile units are designed to allow the operator to strategically position the mobile CPD, then plug it into shore power cables on the back side, while extending the cables from the end of the boom. The vessel’s crew can then reach out, pull the power cables in and plug them into their connection box.

A hydraulic power unit (HPU) is used to power a battery instead of a diesel engine, which is more eco-friendly. The lift, boom and winch movements are all powered by electricity – just like the ships in port while shore power is connected.

The development of mobile CPD units could be what the marine industry needs today to ramp up its efforts to decarbonize operations with the ability to connect more ships each year. These systems are game changers for ports and will facilitate the connection to shoreside electrical power for a variety of ships.

Once the connection has been made using a mobile CPD or a fixed system, the shore-side operator then selects the ship to be connected from the database in an automation system, which determines the proper operating parameters. Protection relays and redundant safety systems ensure the safety of the ship and shore electrical systems.

Custom software allows specialists in a dedicated control center to oversee every connection. All the ship’s systems then run on shore electricity instead of its diesel engines, virtually eliminating fuel emissions while in port.

While meeting the industry’s decarbonization initiatives can seem daunting, the availability of mobile cable positioning devices can cost-effectively facilitate the use of shoreside electricity for a wide range of ships in port. This combination is an important step in achieving the organization’s goals and addressing climate change for ports and the marine industry.

Mike Watts is the president of Seattle-based, Watts Marine, delivering the company's patented shore power solutions to the maritime industry worldwide since 2005 to eliminate millions of tons of air pollutants each year.