Decarbonization of electricity generation has been and will remain the primary lever for reducing global greenhouse gas (GHG) emissions and driving a successful energy transition. According to the International Energy Agency (IEA), the world added a record 295 gigawatts (GW) of renewable generating capacity in 20211.

While the accelerated build-up of renewable generation will be key to meeting both intermediate- and long-term climate targets, no stone can be left unturned on the quest for net zero. To this end, the energy industry must focus on how the transmission and distribution (T&D) portion of the value chain can contribute to GHG reductions.

Since its introduction in the 1950s, sulfur hexafluoride (SF6) has been the gas of choice for circuit-breakers and gas-insulated switchgear (GIS) in high-voltage substations. SF6 possesses unique characteristics that make it particularly well-suited for electrical insulation, current interruption, and arc quenching. However, its environmental impact is significant if it is released into the atmosphere.

The global warming potential (GWP) of SF6 is 25,200 times higher than carbon dioxide (CO2). If leaked, it remains in the Earth’s atmosphere for 3,200 years. While leakage rates in the manufacturing process and during the operation of high-voltage equipment are small, utilities and governing bodies have long recognized the need to minimize the use of SF6. The primary challenge has been a lack of viable alternatives.

This is no longer the case, as extensive research and development activities from equipment vendors in recent years have led to the development of a game-changing technology that uses a new gas mixture consisting of fluoronitrile, CO2, and O2. The mixture’s GWP is more than 100 times lower than SF6 and is a reliable and eco-efficient solution for high-voltage switchgear applications from 72.5 kV up to the ultra-high voltage 1,200 kV.

Understanding high-voltage switchgear operation

High-voltage circuit breakers are subjected to extreme mechanical, electrical, and thermal stress during operation, which makes their design technically challenging. A 420 kV circuit-breaker, for example, is typically required to interrupt fault currents of up to 63,000 Amps in a fraction of a second. The energy released during the interrupting process is comparable to that of a car hitting a wall at around 100 kilometers (approx. 60 miles)/hour. For a very short time, the temperature reached inside the circuit breaker is hotter than the surface of the sun.

SF6 is a synthetic fluorinated compound with exceptional properties, including high dielectric strength and interrupting capacity. These properties allow high-voltage equipment to be very compact.

Modern SF6 circuit breakers utilize GIS technology, which means a gaseous medium is used for both switching (including current interruption) and insulation. GIS technology is reliable and scalable across voltage levels ranging from 72.5 kV up to 1,200 kV. One of the primary advantages it provides when compared to air-insulated switchgear (AIS) technology is a smaller footprint. GIS substations using SF6 are up to 10 times smaller than AIS substations. The reduced size is important, as installations tend to be near urban centers, where land and space are at a premium.

Finding an alternative to SF6 that can achieve the same performance, scalability, and size has been a challenge for equipment providers. Developing compact solutions for high-voltage equipment has proved particularly difficult.

Vacuum circuit breakers combined with synthetic air as the insulation gas are one solution that is being explored as a replacement for SF6. Although synthetic air has a GWP of zero, the technology does have a non-negligible environmental impact when examined more closely.

Air has modest dielectric properties. As a consequence, air-insulated equipment must be comparatively larger and heavier than equipment using advanced alternative gas mixtures. This necessitates the use of additional high-quality materials and manufacturing, which contributes to a larger carbon footprint, hence offsetting the environmental benefit.

Additional space is also required to accommodate the larger equipment, which competes with other needs for land use, such as the preservation of nature, agriculture and/or urban developments. Ultimately, communities do not want to see high-voltage substations become bigger than they currently are, even less so, given the expansion of power grids needed for the energy transition.

Game-changing technology

Over the past decade, several SF6 alternative formulations have been developed and tested in high-voltage equipment none more promising than C4-FN (C3F7CN).

C4-FN is a fluoronitrile-based gas mixture developed by 3M under the commercial name Novec™ 4710 and is specifically suited for high-voltage equipment applications, including GIS, gas-insulated lines, and other switchgear applications, such as Dead Tank Breakers (DTBs) and hybrid switchgear.

In pure form, C4-FN has twice the dielectric strength of SF6. Gas mixtures comprised of C4-FN, CO2, and O2 can be selected for a minimum operating temperature of 30°C to achieve a CO2 equivalent reduction of the insulation gas of 99+% (that is a factor of 100) compared to SF6.

Key advantages include:

- Carbon footprint of the insulating gas is essentially eliminated, while a similar footprint and identical ratings as that of existing SF6 products are maintained, making it suitable for smaller buildings, including legacy GIS installations

- Standardized gas handling practices and training for customer personnel, similar to what is needed for existing equipment

- Economies of scale for gas suppliers and manufacturers of auxiliary equipment

Significant progress has been made over the past two years to commercialize high-voltage switchgear products that utilize the eco-efficient fluronitrile-based gas mixture.

In 2021, one global technology leader launched a new line of high-voltage switchgear products that utilize the eco-efficient fluoronitrile-based gas mixture and plans to offer an SF6-free portfolio across the entire high-voltage switchgear range in the coming years. A 145 kV SF6-free GIS has been commercially available since late 2021.

In August of this year, a breakthrough was achieved with the introduction of a 420 kV (63 kA) SF6-free circuit breaker. The circuit breaker is a key enabler of several high-voltage, eco-efficient switchgear applications that are needed for long-distance power transmission. The circuit breaker has passed all relevant tests described in the IEC and IEEE standards for 63 kA, 5000 A, 50 and 60 Hz. The footprint and dimensions are similar to SF6-based 420 kV circuit-breakers.

World’s first SF6-free 420-kilovolt circuit-breaker

SF6-free 420-kilovolt Gas-Insulated Switchgear

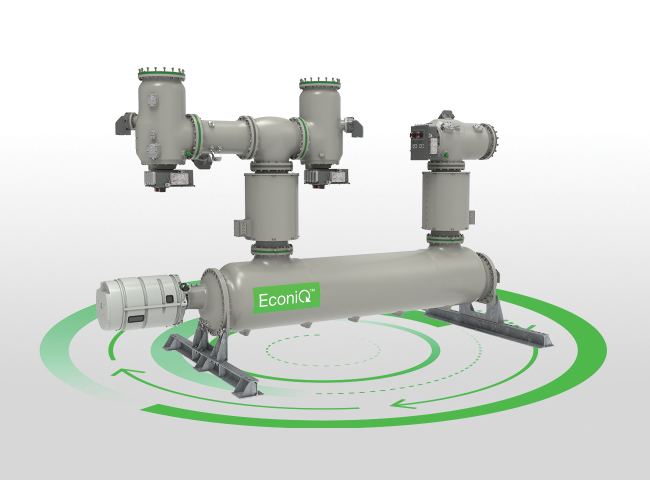

SF6-free 420-kilovolt Dead Tank Breaker

The first installation of the 420 kV circuit-breaker in a DTB is slated for mid-2023, where it will be used at a 345 kV substation owned and operated by US-based energy provider, Eversource. Eversource serves approximately four million customers in the New England region. The project will support the company’s sustainability goals, including meeting targets to achieve carbon neutrality in its operations by 2030. Using innovative technologies to replace or reduce SF6 in the 345 kV transmission system will be a key part of that effort.

The first application of the SF6-free 420 kV circuit-breaker in a GIS will take place in Germany, where three bays of 420 kV GIS will be installed at a substation for TenneT. The project covers a major grid connection upgrade intended to extend the operating life of existing infrastructure and enable efficient long-distance power transmission. The use of the fluoronitrile-based gas mixture will result in the avoidance of ~2,300 kg of SF6, which is equivalent to annual CO2 emissions from 1,150 passenger vehicles2.

Designing for the future

Given the massive up-front investment required to develop and build new T&D infrastructure and upgrade legacy systems, it is important that any alternative to SF6 is scalable and suited for widespread global industrialization. Several manufacturers in Europe, China, and Korea have started using the fluoronitrile-based mixture in their equipment, signaling confidence in its long-term potential and ensuring healthy competition among multiple vendors.

Existing IEC switchgear standards govern the ratings, testing procedures and related requirements of any type of high-voltage switchgear regardless of its technology. IEC standards covering the specific aspects of fluoronitrile-based and other eco-gas mixtures have recently been completed or are under development. An industrial supply chain around the technology is established, with many manufacturers offering auxiliary and gas-handling equipment or services for the mixture.

Additionally, with GHG regulations tightening and evolving around the globe, the total carbon footprint of a product over its entire lifecycle is becoming the commonly agreed upon “gold standard” for judging environmental performance. When it comes to switchgear equipment, looking solely at the gas mixture itself is an oversimplification. Total carbon footprint comparisons favor fluoronitrile-based gas technology, as it allows for a smaller footprint than other SF6-free solutions, including GIS using pressurized air as the insulating medium.

The compactness needed for gas-insulated, high-voltage equipment can only be achieved with the high dielectric performance that comes from using small quantities of fluorinated gas in the mixture. This is a fundamental scientific fact that is acknowledged by virtually all independent industry experts.

Conclusion: Making sustainable grids a reality

The impending build-up of renewable generating capacity in the coming decades will necessitate significant adaptations to existing T&D infrastructure across the globe.

As penetration from wind and solar increases, grids will have to be expanded. On average, power from a wind farm travels around five times the distance from the source to the end-user when compared to a conventional generating source. The longer distance will create the need for higher voltage systems and additional substations. These substations will have to be developed sustainably, without compromising established standards for performance, availability and size.

While SF6 has long served as the insulation and switching medium of choice for high-voltage switchgear, its environmental impact is such that it should be replaced where possible.

Fluoronitrile-based technology has proven to be a reliable, eco-efficient alternative to SF6 and has the potential to significantly reduce the carbon footprint of substations. Because it uses reliable and predictable gas insulation and gas circuit-breaker technology, it can be scaled in a straightforward way. Currently, it is the most practical insulating solution for voltage levels above 52 kV and is widely acknowledged by experts as the best available option to enable a rapid phase-out of SF6 – not only in limited segments but globally for the high-voltage industry.

The development of a 420 kV GIS circuit-breaker using fluoronitrile-based technology represents a groundbreaking achievement that points to new decarbonization pathways for Transmission Systems Operators (TSOs) and utilities. It also paves the way for the technology to be applied at even higher voltage levels and larger ratings in the coming years so that the use of SF6 can eventually be ceased entirely.

Dr. Markus Heimbach is executive vice president and managing director of the High Voltage Products Business Unit within Hitachi Energy.

1 International Energy Agency (IEA)

2 Based on the assumption that a passenger vehicle emits 19 kg CO2 equivalent per 100 km and drives 10,000 km per year